http://www.babwnews.com/2017/11/massive-explosion-rocks-spacex-report/

Massive explosion rocks SpaceX: report

November 26, 2017 By Dan Taylor

Another mishap for SpaceX is prompting concerns about the company, but Elon Musk's brainchild continues to push forward in 2017.

SpaceX has confirmed that its most recent rocket exploded due to unknown reasons earlier this month, as CEO Elon Musk was informed that an engine malfunction caused the rocket to rupture, according to a Washington Post report. In a company statement, Musk said the team followed proper safety protocols at the test facility in McGregor, Texas, and no one was injured.

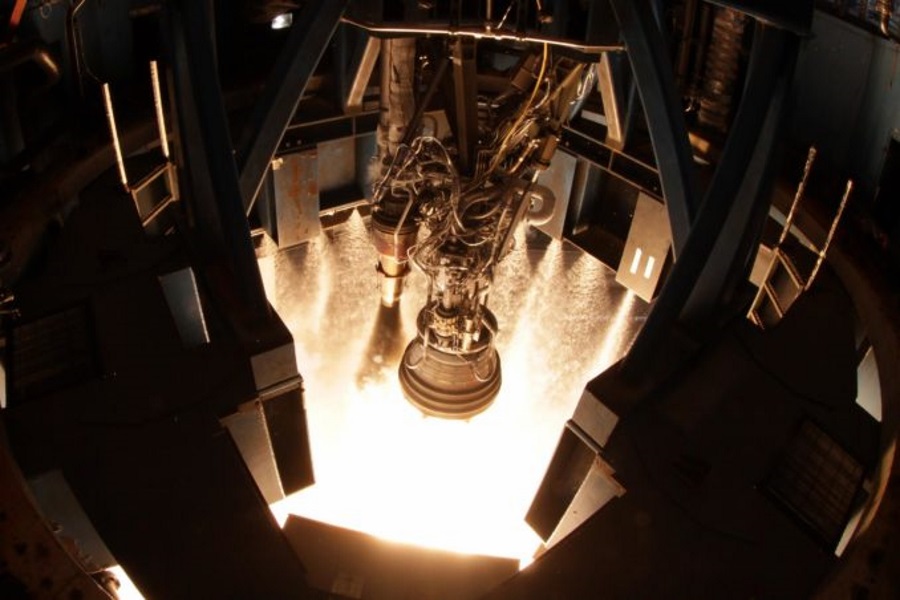

The explosion happened with a Merlin engine, a new technology that hasn’t been tested in flight. SpaceX says they don’t anticipate the mishap will have a negative impact on their “launch cadence.”

“No one was injured and all safety protocols were followed during the time of this incident,” according to a statement from SpaceX as reported by Space dot com. “We are now conducting a thorough and fully transparent investigation of the root cause.

“SpaceX is committed to our current manifest and we do not expect this to have any impact on our launch cadence,” the statement added.

It’s the latest in a series of mishaps for the company. Back in 2015, a Falcon 9 rocket exploded at Cape Canaveral just after it lifted off. It was unmanned, so no one was hurt, but it was a massive loss for the company as the mission was slated to deliver critical cargo to the International Space Station.

Another explosion a year later involved a Falcon 9 on the launchpad before it even lifted off. The rocket was going through an engine test fire at the time, and the resulting investigation took months to determine a cause.

Despite the mishaps, SpaceX has continued to set records, including launching 16 rockets in 2017, double hte usual number and rivaling that of the United Launch Alliance, who SpaceX competes with.

Here’s what SpaceX says about the Merlin engine.

The Merlin engine that powers the first stage of Falcon 9 is developed and manufactured in-house by SpaceX. Burning liquid oxygen and rocket-grade kerosene propellant, a single Merlin engine emits 845 kilonewtons (190,000 pounds) of thrust at liftoff, rising to 914 kilonewtons (205,500 pounds) as it climbs out of Earth’s atmosphere. Merlin’s thrust-to-weight ratio exceeds 150, making the Merlin the most efficient booster engine ever built, while still maintaining the structural and thermal safety margins needed to carry astronauts.

Falcon 9 is the only vehicle currently flying with engine out capability; Falcon 9 can lose up to two of its Merlin engines on the first stage and still complete its mission. The nine-engine architecture on the first stage is an improved version of the design employed by the Saturn I and Saturn V rockets of the Apollo program, which had flawless flight records in spite of engine losses.

Here’s what Wikipedia says about SpaceX’s Merlin rocket engine.

Merlin is a family of rocket engines developed by SpaceX for use on its Falcon 1 and Falcon 9 launch vehicles. SpaceX also plans to use Merlin engines on its upcoming Falcon Heavy launch vehicle. Merlin engines use RP-1 and liquid oxygen as rocket propellants in a gas-generator power cycle. The Merlin engine was originally designed for sea recovery and reuse.

The injector at the heart of Merlin is of the pintle type that was first used in the Apollo program for the lunar module landing engine (LMDE).

Propellants are fed via a single shaft, dual impeller turbopump. The turbo-pump also provides high-pressure fluid for the hydraulic actuators, which then recycles into the low-pressure inlet. This eliminates the need for a separate hydraulic drive system and means that thrust vectoring control failure by running out of hydraulic fluid is not possible.

As of August 2011, SpaceX was producing Merlin engines at the rate of eight per month, planning eventually to raise production to about 33 engines per month (or 400 per year).[3] By September 2013, SpaceX total manufacturing space had increased to nearly 93,000 square meters (1,000,000 sq ft) and the factory had been configured to achieve a maximum production rate of up to 40 rocket cores per year, enough to use the 400 annual engines envisioned by the earlier engine plan.[42] By October 2014, SpaceX announced it had manufactured the 100th Merlin 1D engine and that engines were now being produced at a rate of 4 per week, soon to be increased to 5.[43]

By June 2015, SpaceX was producing Merlin engines at the rate of four Merlin 1D engines per week, with a total production capacity in the factory of a maximum of five per week.[44]

In February 2016, SpaceX indicated that the company will need to build hundreds of engines a year in order to support a Falcon 9/Falcon Heavy build rate of 30 rocket cores per year by the end of 2016.

Massive explosion rocks SpaceX: report

November 26, 2017 By Dan Taylor

Another mishap for SpaceX is prompting concerns about the company, but Elon Musk's brainchild continues to push forward in 2017.

SpaceX has confirmed that its most recent rocket exploded due to unknown reasons earlier this month, as CEO Elon Musk was informed that an engine malfunction caused the rocket to rupture, according to a Washington Post report. In a company statement, Musk said the team followed proper safety protocols at the test facility in McGregor, Texas, and no one was injured.

The explosion happened with a Merlin engine, a new technology that hasn’t been tested in flight. SpaceX says they don’t anticipate the mishap will have a negative impact on their “launch cadence.”

“No one was injured and all safety protocols were followed during the time of this incident,” according to a statement from SpaceX as reported by Space dot com. “We are now conducting a thorough and fully transparent investigation of the root cause.

“SpaceX is committed to our current manifest and we do not expect this to have any impact on our launch cadence,” the statement added.

It’s the latest in a series of mishaps for the company. Back in 2015, a Falcon 9 rocket exploded at Cape Canaveral just after it lifted off. It was unmanned, so no one was hurt, but it was a massive loss for the company as the mission was slated to deliver critical cargo to the International Space Station.

Another explosion a year later involved a Falcon 9 on the launchpad before it even lifted off. The rocket was going through an engine test fire at the time, and the resulting investigation took months to determine a cause.

Despite the mishaps, SpaceX has continued to set records, including launching 16 rockets in 2017, double hte usual number and rivaling that of the United Launch Alliance, who SpaceX competes with.

Here’s what SpaceX says about the Merlin engine.

The Merlin engine that powers the first stage of Falcon 9 is developed and manufactured in-house by SpaceX. Burning liquid oxygen and rocket-grade kerosene propellant, a single Merlin engine emits 845 kilonewtons (190,000 pounds) of thrust at liftoff, rising to 914 kilonewtons (205,500 pounds) as it climbs out of Earth’s atmosphere. Merlin’s thrust-to-weight ratio exceeds 150, making the Merlin the most efficient booster engine ever built, while still maintaining the structural and thermal safety margins needed to carry astronauts.

Falcon 9 is the only vehicle currently flying with engine out capability; Falcon 9 can lose up to two of its Merlin engines on the first stage and still complete its mission. The nine-engine architecture on the first stage is an improved version of the design employed by the Saturn I and Saturn V rockets of the Apollo program, which had flawless flight records in spite of engine losses.

Here’s what Wikipedia says about SpaceX’s Merlin rocket engine.

Merlin is a family of rocket engines developed by SpaceX for use on its Falcon 1 and Falcon 9 launch vehicles. SpaceX also plans to use Merlin engines on its upcoming Falcon Heavy launch vehicle. Merlin engines use RP-1 and liquid oxygen as rocket propellants in a gas-generator power cycle. The Merlin engine was originally designed for sea recovery and reuse.

The injector at the heart of Merlin is of the pintle type that was first used in the Apollo program for the lunar module landing engine (LMDE).

Propellants are fed via a single shaft, dual impeller turbopump. The turbo-pump also provides high-pressure fluid for the hydraulic actuators, which then recycles into the low-pressure inlet. This eliminates the need for a separate hydraulic drive system and means that thrust vectoring control failure by running out of hydraulic fluid is not possible.

As of August 2011, SpaceX was producing Merlin engines at the rate of eight per month, planning eventually to raise production to about 33 engines per month (or 400 per year).[3] By September 2013, SpaceX total manufacturing space had increased to nearly 93,000 square meters (1,000,000 sq ft) and the factory had been configured to achieve a maximum production rate of up to 40 rocket cores per year, enough to use the 400 annual engines envisioned by the earlier engine plan.[42] By October 2014, SpaceX announced it had manufactured the 100th Merlin 1D engine and that engines were now being produced at a rate of 4 per week, soon to be increased to 5.[43]

By June 2015, SpaceX was producing Merlin engines at the rate of four Merlin 1D engines per week, with a total production capacity in the factory of a maximum of five per week.[44]

In February 2016, SpaceX indicated that the company will need to build hundreds of engines a year in order to support a Falcon 9/Falcon Heavy build rate of 30 rocket cores per year by the end of 2016.